By Christine Byrd, Communications Director

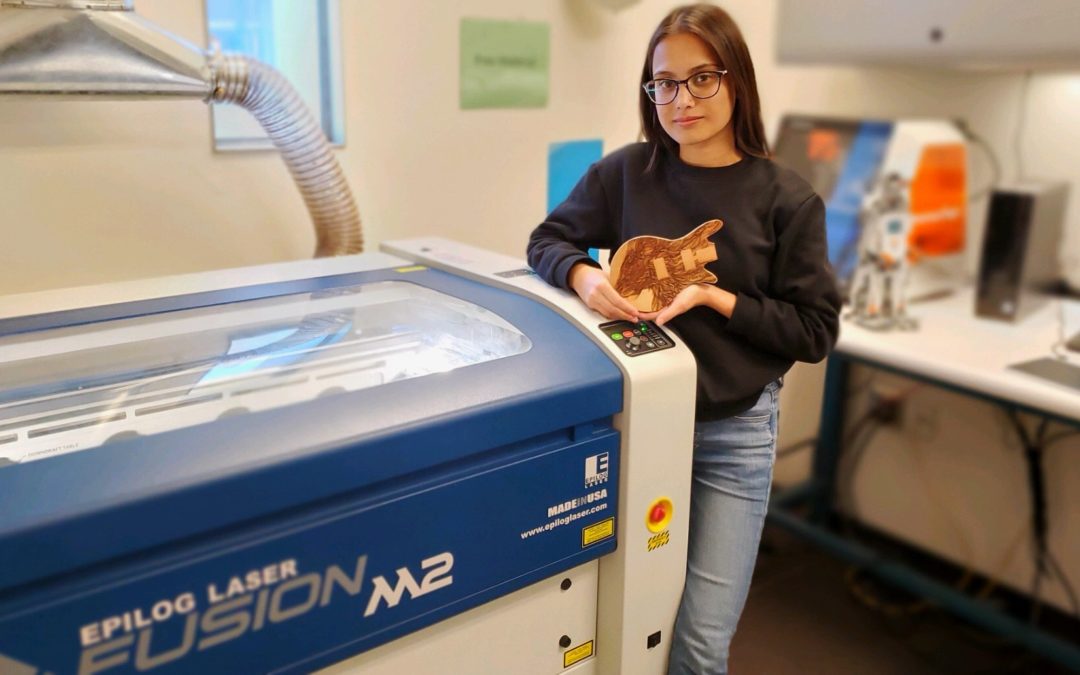

When Soyasha Pandey came to Phoenix from Nepal she had never operated engineering equipment such as laser cutters, bandsaws or 3D printers. Less than two years after starting at South Mountain Community College (SMCC), and spending time each week working in the campus Engineering Lab, she gained hands-on engineering skills to land a full-time job as a lab technician for a local air conditioning company.

“The fact that I knew how to use power tools, 3D printers and 3D design software like SolidWorks was a big influence in getting the internship that turned into the job,” says Pandey.

She’s one of an estimated 1,000 SMCC students who have gained hands-on engineering skills with industry-quality equipment in the Engineering Lab since it opened in 2018.

Hands-on Training

The Engineering Lab is the cornerstone of a partnership forged between SMCC and Base 11, which installed an MIT-inspired Fab Lab on the campus. The lab includes manufacturing equipment that students learn to use through formal courses or individual projects. While other Maricopa County Colleges may have similar equipment scattered across their campuses, SMCC is unique because its equipment is all in one lab.

The benefit of having everything under one roof, explains lab manager Suzan Allaham, is that students get exposed to tools and equipment they might otherwise never have seen.

“When they’re coming here to 3D print, they will see someone using the laser cutter, and it increases their curiosity to learn about it,” says Allaham. “Or they might see the ShopBot and ask, ‘What’s this big machine?’ It creates questions for the students and they might discover more things they love, learn about, and to use to create.”

That’s exactly how Pandey says she became proficient with so much of the lab’s technology.

“Almost everything on my résumé has come through being able to work in the Engineering Lab,” she says. “Coming from Nepal, there was a big difference between what a woman does and what a man does, so I had never had access to something like power tools. It’s been a big confidence booster.”

SMCC opened the engineering lab at the same time it revamped its engineering curriculum, including bringing a Solidworks certification course to the campus, thanks to Base 11’s strong partnership with Dassault Systèmes, the company that owns SolidWorks.

“The Engineering Lab allows us to shift our program from an academic engineering pursuit to more of an engineering tech background,” says Stephen Hustedde, interim Dean of Academic Innovation at SMCC. “It helps students get jobs as engineering technicians, or go on to 4-year degree programs.”

Hustedde says the lab and the re-envisioned curriculum helped create a “perfect storm” which led to the engineering program doubling its enrollment within one year.

Industry-quality Experience

Ulises Contreras is one of the students who has completed projects in the lab, and even earned a Solidworks certification. That industry-level certification is in-demand across a wide range of industries, from engineering to electronics and defense to medical science. Contreras fully expects the certification, combined with the hands-on skills he gained in the lab, to advance his career.

A father of three who works in hotel maintenance, Contreras spent three to five hours each week working in the Engineering Lab, gaining expertise with the equipment, in addition to his engineering courses at SMCC. He says the lab was like a home to him.

“Being from a family of laborers, I am the first generation exposed to such education,” says Contreras. “I realized, ‘Wow, I can compete.’ The knowledge that I have these skills has given me a lot of confidence.”

“Being from a family of laborers, I am the first generation exposed to such education,” says Contreras. “I realized, ‘Wow, I can compete.’ The knowledge that I have these skills has given me a lot of confidence.”

Contreras collaborated in a team that used Legos to build and program a robotic desert tortoise, and then, on his own, he designed and built a fully operational deadbolt with keys. One of the greatest joys of the projects, he says, was working on them in front of his three young daughters, and hearing them pick up the engineering vocabulary he was using.

“The vocabulary I use when I’m designing with Solidworks is something I missed when I was a kid, but my daughters always see me working on and I know I’m giving to them something I didn’t have,” he says.

Contreras, who has completed his associate’s degree, plans to continue his studies in civil engineering at Arizona State University.

21st Century STEM Leaders

While engineering students like Pandey and Contreras are required to complete projects in the lab, it’s not the only way students are gaining hands-on skills. Allaham constantly finds creative ways to engage students from disciplines beyond science, technology, engineering and math. For example, a class of history students learned to use the Engineering Lab to print 3D models of important historical figures. And when the campus’ botanical garden needed new signage, students in the Engineering Lab designed and manufactured the signs.

“We can help students create whatever they are thinking about,” says Allaham. “We are here to support them.”

Allaham has worked hard to make the Engineering Lab a welcoming place, not just for students working on projects, but to study and socialize. And the results are telling: in 2019, she tracked more than 3,400 visits to the lab from about 500 individuals.

Base 11 sees the revitalization of SMCC’s engineering program as a model for other community colleges that want to prepare more students for jobs in Next Frontier industries, ranging from data analytics to advanced manufacturing.

“South Mountain Community College is a perfect example of rethinking 21st century STEM education to be more hands-on and experiential, to the benefit of its students and its local industry,” says Ingrid Ellerbe, executive director of Base 11. “We’re excited to see so many students in the area gaining the skills needed to excel on their STEM pathways.”

The outcomes for SMCC students who are not only transferring to four-year degrees, but landing STEM jobs with their skills, have impressed Hustedde, as well.

“We’ve been able to leverage the foundation from Base 11, to provide additional programs and benefits for our students,” Hustedde says. “I think it’s surpassed what we envisioned.”